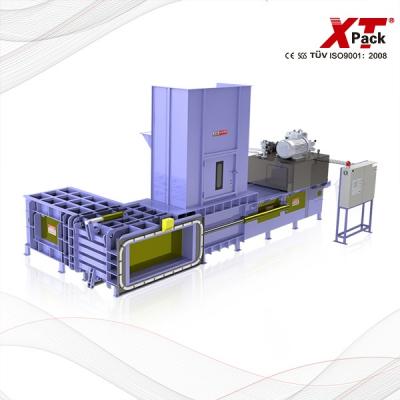

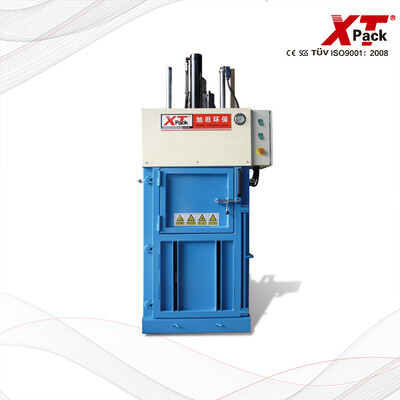

When it comes to efficient handling and managing cardboard waste, businesses need reliable and effective solutions. One such solution is the semi-auto baler machine, which offers various benefits and is readily available for sale. These machines are specifically designed for cardboard compaction, allowing businesses to streamline their waste management processes and maximize space utilization. This article will explore the advantages of using semi-auto baler machines and why they are a popular choice for businesses in need of efficient cardboard compaction.

Streamlined Waste Management

Efficient waste management is crucial for businesses looking to minimize costs and reduce their environmental impact. Semi-auto baler machines provide a streamlined approach to cardboard compaction, allowing businesses to quickly and effectively compress their waste. This compression significantly reduces the volume of cardboard, making it easier to handle and transport. With a semi-auto baler machine, businesses can efficiently manage their cardboard waste without the need for excessive manual labor or time-consuming processes.

Space Optimization

One of the main advantages of using semi-auto baler machines is the significant space optimization they offer. By compacting cardboard waste, these machines allow businesses to make better use of their available storage space. This is particularly important for businesses that generate large quantities of cardboard waste on a daily basis. Instead of storing bulky and inefficiently stacked cardboard boxes, a semi-auto baler machine compacts the waste into neat and manageable bales. These bales can be easily stored and stacked, maximizing storage capacity and creating a more organized work environment.

Cost Savings

Implementing a semi-auto baler machine for cardboard compaction can lead to substantial cost savings in the long run. By reducing the volume of waste, businesses can significantly reduce their waste disposal costs. Additionally, the compacted bales generated by these machines can be sold to recycling companies, providing an additional source of revenue. With the ability to earn money from their cardboard waste and decrease disposal costs, businesses can enjoy a positive return on investment when purchasing a semi-auto baler machine.

Increased Efficiency and Productivity

Semi-auto baler machines contribute to increased efficiency and productivity in the workplace. These machines require minimal manual labor and can handle large volumes of cardboard waste in a short span of time. By automating the compaction process, businesses can free up valuable employee time and redirect it towards more productive tasks. This results in improved overall efficiency and higher productivity levels within the organization.

In conclusion, semi-auto baler machines are a reliable and efficient solution for businesses in need of effective cardboard compaction. With streamlined waste management, space optimization, cost savings, and increased efficiency, these machines offer numerous benefits to businesses of all sizes. Whether it's a retail store, warehouse, or manufacturing facility, a semi-auto baler machine can significantly improve waste management processes and contribute to a more environmentally friendly operation. With the availability of semi-auto baler machines for sale, businesses can easily invest in this technology and enjoy the advantages it brings to their cardboard compaction efforts.