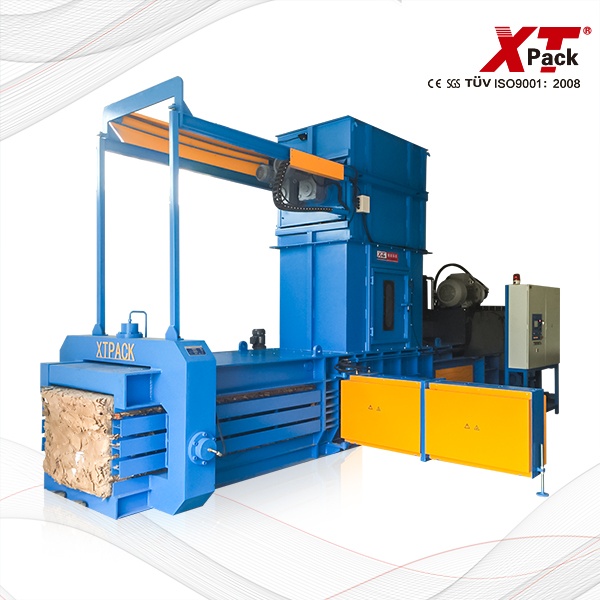

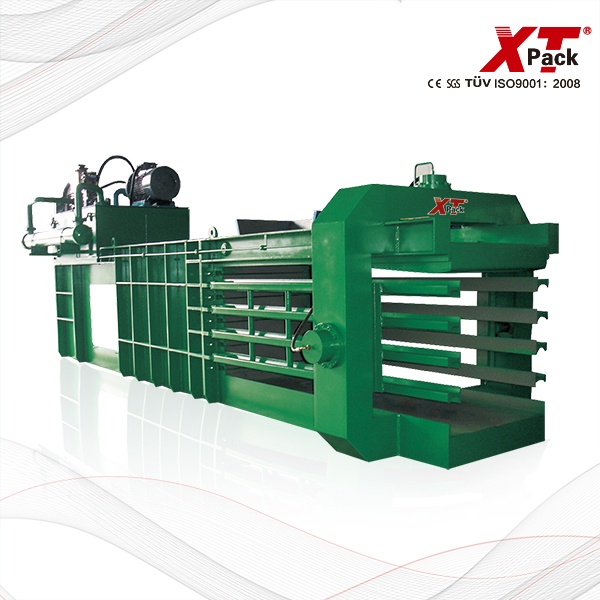

Usage of Large-sized Full AutomaticTwo RamBalers

The two ram baler not only can achieve maximum bale weight, but can also bale many different materials including OCC, plastic film, HDPE, PET, aluminum cans, steel cans, various plastic bottles, plastic baskets, waste tyres, waste household appilances (such as refrigerators, washing machines microwave ovens ), aluminum alloy frame, iron sheet etc.

Features of Large-sized Full AutomaticTwo RamBalers

Equipped with American ACCENT auto tie unit, high efficiency, low failure;

All cylinders stroke is controlled by sensors with accuracy 0.1mm;

The width of the bale can be revised according to different materials, and the door opening mechanism automatically adapts to ensure the maximum bale density;

With extremely high strength knives, easy to install, quick to replace, convenient for maintenance;

Equipped with Sweden HARDOX wearing liners, giving our customers longer run time between scheduled maintenance and replacement.

Main Ram with special design can be quickly removed from the chamber, convenient maintenance;

Automatic sensing of material volume in the hopper, automatically control the feeding device while baling;

The number of strapping lines and strapping distance can be adjusted as needed;

According to different materials, corresponding programs can be selected, such as plastic bottles/waste paper/films/scrap metals programs, greatly improving the compression efficiency and capacity;

Compared with channel balers, two ram balers offer greater material processing flexibility. The completely enclosed, heavily reinforced baling chamber allows for easier processing of a wider range of materials.

Built with a solid uni-body sidewall construction. They are designed and built specifically as one piece to reduce weak points creating a more structurally sound machine for longer lifetime and greater reliability.

| Model | XTR-1250W11075-75 | XTR-1250W15075-75 | XTR-2000W11075-150 | XTR-2000W15075-150 | XTR-2200W15085-200 |

| Pressure | 125tons | 125tons | 200tons | 200tons | 220tons/250tons |

| Main Motor Power | 55kW | 55kW | 55kW×2 | 55kW×2 | 75kW×2/55kW×2 |

| Cooling System | Air cooler/water cooler | ||||

| Cycle Time(Unload) | 18s | 18s | 10s | 12s | 14s/20s |

| Number of Belting | Set as per demand | ||||

| Tying | Wire/PET Strap/Film Wrapping | ||||

| Feeding Opening Size(L×W) | 1780×990mm | 1900×1390mm | 1780×1026mm | 1900×1390mm | 2650×1390mm 1900×1390mm |

| Bale Size (L×H×W,W can be adjustable) | 1100×750×(1150-1350)mm | 1500×750×(900-1100)mm | 1100×750×(1150-1350)mm | 1500×750×(900-1100)mm | 1500×850×(900-1100)mm |

| Bale Density(OCC) | 450-550kgs/m³ | 450-550kgs/m³ | 500-600kgs/m³ | 500-600kgs/m³ | 550-700 kgs/m³ |

| Throughput(30-60kgs/m³) | 8-12tons/h | 13-17tons/h | 15-20tons/h | 17-22tons/h | 20-40tons/h 18-25tons/h |

Machine Weight | 21tons | 25tons | 30tons | 32tons | 42tons/37tons |

| Machine Overall Dimension | 8800×4500×3550mm | 8300×5300×3550mm | 8800×4500×3600mm | 8300×5300×3600mm | 9800×5600×3660mm 8300×5600×3660mm |

Feeding Device (optional) | Iron conveyor | Iron conveyor | Iron conveyor | Iron conveyor | Iron conveyor |