- Home

- Baler Machines >

-

Baler Accessories

>

Engineering Oil Cylinder Pre-compaction Flap Cardboard Shredder Flexible Straps PET Straps Iron Wires Quick-Lock Galvanized Steel Wires Sorting Conveyor Belt Conveyor Semi-Automatic Strapping Machine Dust Removal Device Pipes Cooling Tower PET/PP Strapping Dispenser Pneumatic Strapping Machine Electric Strapping Machine Manual Strapping Tool Shredding Fan Iron Conveyor Drum-Style Cyclone Plate Separator Balance Bottle Perforator Carton Shredder Bin Baler Cardboard & Paper Core Shredder Paper Core Shredder Bin Lifter

- Baler Application >

- Solid Waste Disposal System >

- Support >

- About Us >

- Service >

-

Solution

>

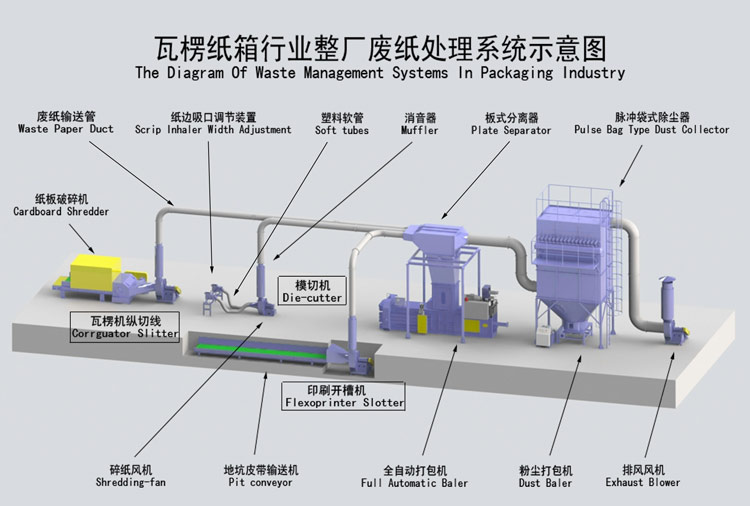

The Diagram of Waste Management Systems in Packaging Industry The Diagram of Plastics Film, Non-Wolven Scrap Trims Management Systems The Diagram of Waste Paper & Dust Management Systems in Printing Industry The Diagram of Waste Disposal System in Paper Making Industry The Diagram of Urban Waste, Solid Waste, RDF Sorting, Baling and Wrapping System

- Contact Us

- Email Us