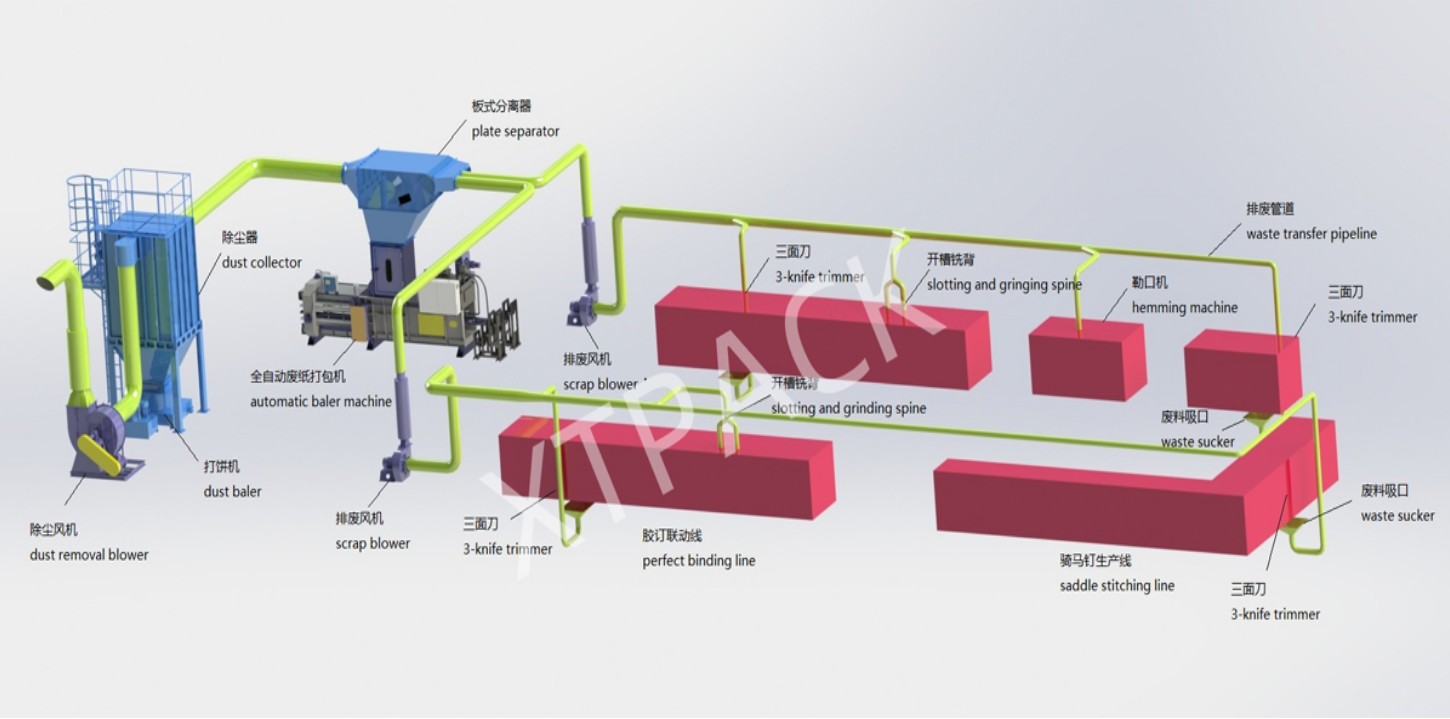

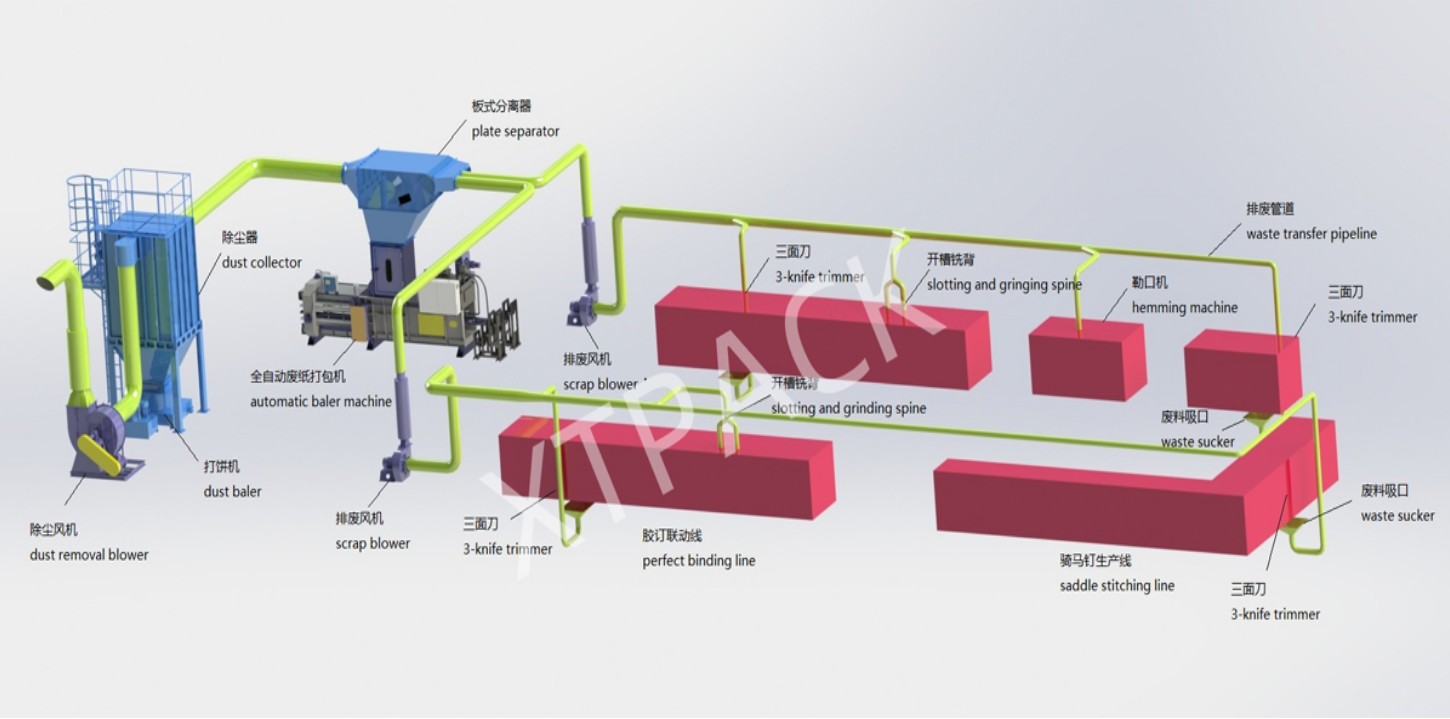

Printing Factories Paper Scrap& Dust Disposal System

Professional for the printing industry’s waste paper collecting and baling system to provide a reasonable and efficient design, stable operation, reduces dust pollution, waste paper recycling efficiency significantly improved. It has solved the waste discharge problems of the equipment such as binding moving lines, Nail riding linkage line, glue binding machine, three-knife trimmer etc.

The waste scraps are sucked into the blower, after being cut off, the scraps are transported to the cyclone through duct finally fallen into the waste paper baler. The dust air flows into the bag-type or pulse-type dust collector, and the clean air is discharged into indoor or outdoor. Dust through the professional dust baler compressed into blocks, convenient for accumulation and transportation. The complete system dust removal efficiency can up to 99%, is the ideal waste disposal system for printing industry.

Related Baler Machine

Textile/ Clothes/ Wool/ Cotton BalersNovember 14, 2016Textile/Clothes/Wool/Cotton Balers are widely used to compress second-hand clothing, comforters, shoes, wool, cotton etc. Hydraulic lifting chamber door improves the work efficiency, conveniently for packaging and the '#' tying.

Pressure: Up to 150 tonview

Textile/ Clothes/ Wool/ Cotton BalersNovember 14, 2016Textile/Clothes/Wool/Cotton Balers are widely used to compress second-hand clothing, comforters, shoes, wool, cotton etc. Hydraulic lifting chamber door improves the work efficiency, conveniently for packaging and the '#' tying.

Pressure: Up to 150 tonview Kitchen Garbage BalersNovember 16, 2016Kitchen Garbage Balers are specially designed for dealing with different kinds of waste in kitchen like food residue, disposable tableware etc. Their small bodies also make them popular in vessel, harbor, restaurant, hospital etc.

Pressure: 1-5 tonsview

Kitchen Garbage BalersNovember 16, 2016Kitchen Garbage Balers are specially designed for dealing with different kinds of waste in kitchen like food residue, disposable tableware etc. Their small bodies also make them popular in vessel, harbor, restaurant, hospital etc.

Pressure: 1-5 tonsview Medium-sized Full Automatic BalersNovember 16, 2016Medium-sized Full Automatic Balers are widely used for compressing waste cardboard, carton, paper, plastic film, straw etc.

Pressure: 60-80 tons

Feed Opening Size:

Min.1300*1050mm, Max.2400*1050mm

Bale Size: L*1100*750mm

Production Capacity: 3-9 tview

Medium-sized Full Automatic BalersNovember 16, 2016Medium-sized Full Automatic Balers are widely used for compressing waste cardboard, carton, paper, plastic film, straw etc.

Pressure: 60-80 tons

Feed Opening Size:

Min.1300*1050mm, Max.2400*1050mm

Bale Size: L*1100*750mm

Production Capacity: 3-9 tview