As we step into the 21st century, intelligent manufacturing has become the key direction for the transformation and upgrading of various industries. With the continuous rise in labor costs and higher requirements for production efficiency and environmental standards, traditional manual processing methods have gradually exposed problems such as low efficiency, high error rates, and difficult management. Therefore, accelerating the promotion of automated solid waste treatment equipment has become a wise choice for many manufacturing and recycling enterprises to enhance their competitiveness.

What Is A Fully Automatic Baler?

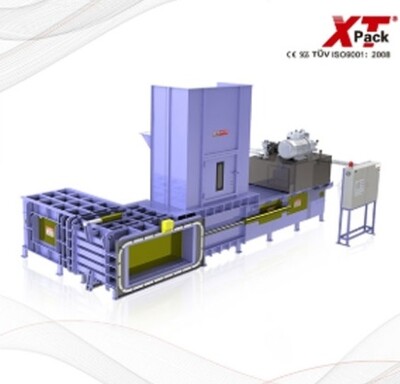

A fully automatic baler is a type of automated equipment specifically used for the recycling and processing of solid waste, particularly suitable for compressing and packaging lightweight materials such as non-woven fabrics and melt-blown fabrics. This equipment can achieve full-process automation, completing operations such as compression, baling, and binding automatically without manual intervention. After forming the bale, PP strapping is used for fixation, effectively reducing the use of consumables and saving packaging costs. It is an efficient tool for recycling enterprises.

Three Core Advantages Of The Fully Automatic Baler

High efficiency and convenience, saving labor costs

The equipment has a high level of automation and can start automatic cyclic compression and baling with just the input of materials. Compared to traditional manual or semi-automatic operations, it can significantly improve packaging efficiency, reduce labor involvement and operational errors, and is particularly suitable for handling large, low-density solid waste.

Integrated design, stable operation

The equipment has a compact structure design, a small footprint, and integrates multiple functions such as unpacking, bottom sealing, compression, and binding. It can run stably for a long time in high-load, high-frequency industrial environments. At the same time, it uses high-strength steel and an intelligent control system to ensure that the equipment remains reliable and durable even in extreme environments.

Reduce consumables, environmentally friendly

Through automatic precise compression control and PP strapping fixation, it can minimize packaging material waste, thereby reducing operating costs. The equipment also reduces material waste due to manual operation, improves recycling efficiency, and complies with the concepts of green environmental protection and sustainable production.

The fully automatic baler launched by XTpack Baler is not only suitable for the recycling and compression of waste such as non-woven fabrics and melt-blown fabrics, but is also widely used in the solid waste processing links of industries such as textiles, medicine, logistics, e-commerce, and manufacturing. Its simple operation, low maintenance cost, and excellent compression effect have made it a key piece of equipment to improve production line efficiency and environmental standards. In the future market trend of continuous growth in solid waste management and regenerative resource processing, the XTpack Baler fully automatic baler will continue to promote the intelligent and green development of the industry, creating higher production value and environmental responsibility for enterprises.