In a time where environmental concerns are at the forefront of global issues, industries worldwide are making efforts to adopt eco-friendly practices. This is particularly true for the automotive industry, which has come a long way in reducing its carbon footprint. One such practice that has gained popularity is the use of baler machines to manage plastic waste. In this blog post, we will explore the significance of these machines in the automotive industry and discuss how they can contribute to a greener future.

The Importance of Eco-Friendly Practices in the Automotive Industry

As one of the major contributors to air pollution and waste generation, the automotive industry plays a crucial role in promoting sustainability. With increasing consumer demand for environmentally friendly solutions, automakers are continuously striving to reduce their impact on the environment. From manufacturing processes to vehicle design, eco-friendly practices are being integrated at every step of the way.

Plastic Waste: A Challenge for the Automotive Industry

Plastic waste is a significant concern for the automotive industry. With the extensive use of plastic components in vehicles, the industry is obliged to find effective ways to manage and recycle this material. Plastic waste not only contributes to landfills but also affects natural ecosystems, marine life, and overall environmental health. In response to these challenges, the automotive industry is embracing innovative solutions such as the baler machine.

Baler Machine: A Game-Changer for Plastic Waste Management

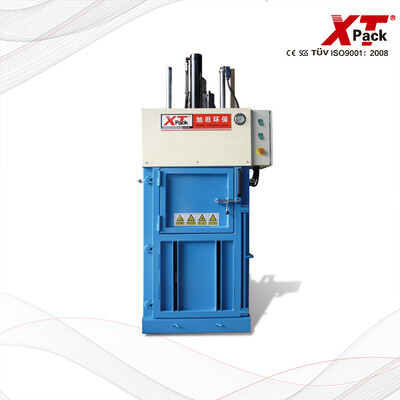

A baler machine is a powerful piece of equipment used to compress and bind waste materials, including plastics, into manageable bales. This process not only reduces the volume of waste but also facilitates proper storage and transportation. By using a baler machine, the automotive industry can effectively handle its plastic waste while promoting recycling and reducing landfill contributions.

Plastic Baler Machine for Sale: Investing in a Greener Future

For automotive companies looking to incorporate sustainable practices into their operations, investing in a plastic baler machine for sale is highly beneficial. These machines provide a cost-effective and efficient solution for plastic waste management. By compacting plastic waste into bales, companies can minimize storage space requirements, improve waste handling processes, and enhance recycling efforts.

Moreover, the sale of plastic baler machine presents an opportunity for automotive companies to generate additional revenue streams. As the demand for recycled plastics increases, automotive manufacturers can sell their baled plastic waste to recycling facilities, creating a circular economy within the industry.

The automotive industry is making significant strides towards adopting eco-friendly practices, and the use of baler machines for plastic waste management is a notable example. By investing in a plastic baler machine for sale, automotive companies can effectively manage their plastic waste, promote recycling, and reduce their overall environmental impact. As the demand for sustainable solutions continues to rise, embracing such innovative technologies can help pave the way for a greener, more sustainable future in the automotive industry.