In the quest for sustainable solutions and environmental conservation, the rubbish compress machine has emerged as a transformative technology. This innovative device offers a game-changing approach to waste management, tackling the challenges of waste volume and disposal. In this blog, we'll delve into the world of rubbish compress machines, exploring their significance, working principles, and potential impact on our environment.

The Rubbish Compress Machine: A Glimpse into Innovation

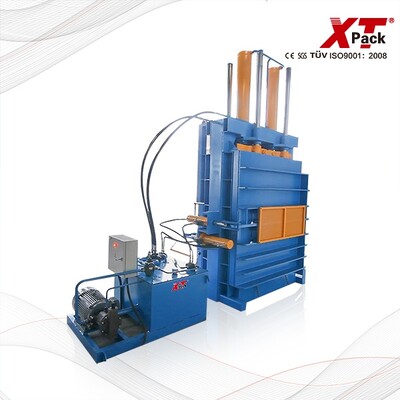

Rubbish compress machines are at the forefront of modern waste management strategies. These machines are designed to reduce the volume of waste materials, thereby minimizing storage space and transportation costs. By compacting various types of waste, from plastic and paper to cardboard and cans, these devices pave the way for more efficient and sustainable waste handling.

Working Principles of Rubbish Compress Machines

The core mechanism of a rubbish compress machine involves applying pressure to waste materials, causing them to shrink in volume. This is achieved through hydraulic or mechanical systems that exert force on the waste, compacting it into tightly compressed blocks or bales. The resulting compacted waste is not only easier to store and transport but also reduces the frequency of waste collection and disposal. Rubbish compress machines not only reduce the volume of waste but also contribute to waste segregation. By compacting waste into separate blocks based on material type, these machines streamline recycling efforts and enhance the efficiency of downstream recycling processes.

The Environmental Impact and Benefits

One of the most significant advantages of rubbish compress machines is their potential to alleviate the burden on landfills. By compacting waste, these machines extend the lifespan of landfills, as more waste can be accommodated in the reduced space. This, in turn, helps in preserving valuable land resources and minimizing the environmental impact of landfills. The compacted waste produced by rubbish compress machines requires less frequent transportation, leading to a reduction in carbon emissions associated with waste collection and disposal. This aligns with sustainable practices and contributes to lowering the overall carbon footprint of waste management operations.

Future Prospects and Sustainability

Rubbish compress machines exemplify the ongoing efforts to create a greener and more sustainable future. As technology advances, we can expect further innovations in waste management machinery, leading to even more efficient waste reduction and resource recovery. The integration of smart technology and data analytics could enhance the precision and effectiveness of these machines, optimizing waste management processes further. Beyond the mechanical aspect, rubbish compress machines can also play a role in fostering community engagement and awareness about waste management. The visual impact of seeing waste being compacted into smaller volumes can highlight the importance of waste reduction and recycling, encouraging individuals to adopt more responsible waste disposal habits.

In a world grappling with waste-related challenges, rubbish compress machines offer a beacon of hope. By compressing waste and enhancing waste management processes, these devices pave the way for reduced environmental impact, efficient resource utilization, and a cleaner planet. As we embrace the potential of rubbish compress machines and continue to invest in waste management technologies, we take another step toward a more sustainable future for generations to come.