Waste paper is one of the most commonly recycled items at recycling stations. As the volume of accumulated waste paper grows, it takes up a large area. Messy piles of waste paper can also create difficulties during transportation when loading onto trucks for further processing, consuming labor and leading to unnecessary manpower and transportation costs. Moreover, as government regulations on environmental standards for recycling stations become stricter, messy and unorganized recycling stations are increasingly being disallowed. Therefore, from multiple perspectives, bundling waste paper neatly has become very important for the operation of recycling stations.

How to Choose the Right Waste Paper Baler?

When dealing with piles of waste paper, selecting an efficient waste paper baler is crucial. A waste paper baler helps recycling stations quickly compress waste paper into compact bales, reducing the space waste paper occupies and minimizing manual intervention. There are many types of waste paper balers on the market, and recycling stations should choose the right equipment based on their actual needs, considering factors such as processing capacity, ease of operation, and ease of maintenance, ensuring an efficient baling process.

Improving Work Efficiency and Reducing Costs

Using a waste paper baler and an industrial paper shredder baler can significantly improve waste paper processing efficiency. Traditional manual bundling is not only inefficient but also often results in unregulated handling of waste paper, causing waste and disorder. With a waste paper baler, the entire baling process is automated, and one-button operation saves the recycling station a substantial amount in labor costs. At the same time, the industrial paper shredder baler can compress shredded paper and waste paper into standard-sized bales, making stacking and transportation easier, thus reducing transportation costs and minimizing the need for manual handling.

Ensuring Cleanliness and Improving the Neatness of the Work Area

When waste paper piles up at a recycling station, it not only affects hygiene but also creates a messy work environment. After using a waste paper baler, the waste paper is compressed into compact bales, significantly reducing the area occupied by the piles. This not only improves the utilization of space at the recycling station but also prevents waste paper from scattering in the work area, reducing the cleaning workload. The industrial paper shredder baler can also quickly bundle shredded paper, preventing paper scraps from scattering and keeping the work area tidy.

Promoting Standardization of Waste Paper Recycling and Saving Storage Space

By using a waste paper baler, a recycling station can bundle a large amount of waste paper into uniformly sized bales, making the recycling process more standardized. This method of bundling not only improves recycling efficiency but also facilitates the transportation and storage of waste paper. The industrial paper shredder baler can also efficiently compress waste paper during processing, saving storage space and making it easier for secondary recycling and reuse.

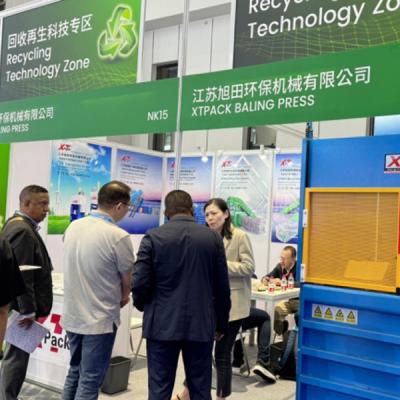

The rapid bundling of waste paper is not only about improving efficiency but also about meeting environmental standards and ensuring the regulated operation of recycling stations. Waste paper balers and industrial paper shredder balers help recycling stations handle waste paper more efficiently, save space and costs, improve work efficiency, and ensure the cleanliness of the recycling station's environment. XTPACK provides efficient and energy-saving baling equipment to support the smooth operation of your waste paper handling tasks.