Deep-sea mining has gained significant attention in recent years due to its potential to extract valuable minerals from the ocean floor. However, its environmental impact cannot be ignored. As responsible stewards of our oceans, it is crucial to mitigate the adverse effects of deep-sea mining operations. This blog will delve into a powerful tool for environmental impact mitigation - the Marine Garbage Compactor. Discover how this innovative technology can contribute to reducing marine pollution and safeguarding the fragile ecosystems of the deep sea.

The Consequences of Deep-Sea Mining

Deep-sea mining involves extracting minerals from the ocean floor, using heavy machinery and equipment. Unfortunately, this activity can result in significant environmental consequences. These include physical disturbances to the seafloor, destruction of habitats, disruption of underwater ecosystems, and the release of harmful pollutants into the marine environment. To combat these challenges, it is imperative to develop efficient and sustainable solutions that mitigate the impact of deep-sea mining activities.

The Role of Marine Garbage Compactor

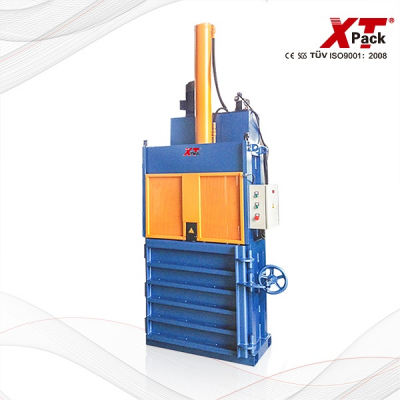

One promising tool in combatting marine pollution caused by deep-sea mining is the Marine Garbage Compactor. This advanced technology aims to reduce the amount of waste generated during mining operations and prevent its dissemination into the surrounding waters. The compactor effectively compacts and stores various forms of marine litter, such as plastics, metals, and other debris, in a compact and manageable form. By minimizing the dilution of pollutants, the Marine Garbage Compactor helps preserve the marine ecosystem and mitigates the damaging effects of deep-sea mining on ocean life.

Benefits of Marine Garbage Compactor Implementation

Implementing the Marine Garbage Compactor has numerous benefits. Firstly, it facilitates the proper and responsible disposal of waste generated during deep-sea mining activities. By reducing the volume of garbage, fewer pollutants are released into the surrounding environment, greatly diminishing the impact on marine life. Moreover, the compactor enables efficient storage and transportation of compacted waste, making it easier to monitor and manage the disposal process. This technology also contributes to the maintenance of clean oceans, aligning with global efforts to achieve sustainable development goals and marine conservation targets.

Promoting a Sustainable Future through Collaboration

Collaboration between various stakeholders is vital for the successful implementation of the Marine Garbage Compactor. Governments, scientific communities, and deep-sea mining companies must work together to ensure the integration of this technology into mining operations. Funding and investment in research and development can further enhance and optimize the compactor's efficiency. Additionally, educating the public about the importance of responsible deep-sea mining practices and the role of the marine garbage compactor can generate public support and foster a collective commitment towards conserving our oceans.

As the demand for minerals from the deep-sea continues to grow, it is critical to prioritize sustainable practices to reduce the environmental impact of mining activities. The Marine Garbage Compactor provides an effective solution to mitigate marine pollution caused by deep-sea mining. By implementing this technology, we can work towards safeguarding fragile ecosystems, preserving marine biodiversity, and ensuring a sustainable future for our oceans.