In daily operations, waste management is a common challenge faced by many industries. Whether in the foodservice industry, commercial complexes, or factories, the accumulation of waste can take up a significant amount of space and put considerable pressure on cleaning operations. In this process, the rubbish compress machine plays a crucial role as an efficient waste management tool. Although its work is not highly visible, it contributes greatly to maintaining cleanliness and improving operational efficiency.

Easy to Operate

In high-traffic locations, such as restaurants or shopping malls, a large amount of waste is generated daily, especially food scraps and disposable tableware. If not handled promptly, this waste can occupy valuable space and impact the cleanliness of the work environment. The design of the rubbish compress machine places a strong emphasis on ease of operation. With just the press of a button, the machine automatically compresses the waste, significantly reducing the manual workload and minimizing the issues caused by waste accumulation.

Solving Space Limitations

For many recycling stations or the foodservice industry, waste often piles up and takes up a lot of storage space. Particularly with cardboard, plastic, and other bulky waste, improper handling can lead to severe space constraints. The use of the rubbish compress machine can compact these waste materials into tight, small packages, significantly reducing the space they occupy and making waste storage more organized. This not only increases the utilization of storage space but also prevents messy waste piles.

Ensuring Cleanliness and Safety

Improper storage and handling of waste can lead to hygiene issues, especially with perishable food scraps. In traditional waste management methods, scattered rubbish not only emits unpleasant odors but can also become a breeding ground for bacteria. By using the rubbish compress machine, waste is quickly compressed into packages, reducing the chance of spillage and leakage, which greatly improves environmental hygiene. The machine's efficient handling also reduces the risk of cross-contamination, creating a cleaner and safer environment in the workplace.

Long-Term Use

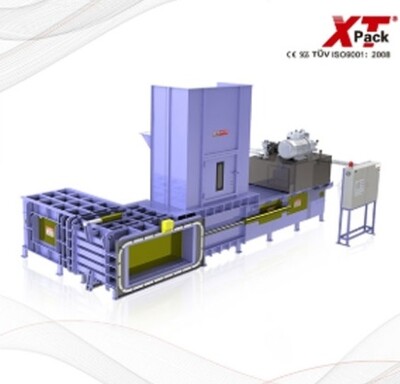

The rubbish compress machine is equipped with an advanced hydraulic system, offering strong compression capability and stable performance. Even with frequent daily use, the machine can maintain high operational efficiency. Its durability ensures that recycling stations or foodservice establishments can use the machine for a long time without the need for frequent maintenance, saving time and costs. Only regular checks and cleaning are required to keep the machine functioning effectively.

Although the role of the rubbish compress machine may not be immediately visible in daily waste management, its efficient compression, ease of operation, and stable performance undoubtedly make it the "unsung hero" of modern environmental management. XTPACK is dedicated to providing high-quality rubbish compress machines to help various industries easily tackle the challenges of waste management. If you are also facing waste disposal issues, XTPACK's equipment will be your ideal choice.