In our ongoing quest to reduce waste and promote sustainability, innovative technologies have emerged as game-changers in the recycling industry. Among these technologies, plastic bottle baler innovations stand out as a powerful solution for maximizing recycling efforts. In this blog, we'll explore how these cutting-edge baler machines are revolutionizing recycling and reducing environmental impact.

The Evolution of Plastic Bottle Balers

Plastic bottle balers have come a long way since their inception. Early baler models were manual and relatively inefficient, but today's innovations have turned them into sophisticated machines that cater to a wide range of industries. These innovations are designed to tackle the challenges of recycling plastic bottles more effectively and efficiently.

Automatic Baling Technology

One significant innovation in plastic bottle balers is the introduction of automatic baling technology. These machines can automatically collect, compress, and bale plastic bottles without the need for constant manual operation. This feature not only reduces labor costs but also significantly increases the volume of plastic bottles that can be processed, making recycling more efficient.

Variable Baling Options

Modern plastic bottle balers offer variable baling options, allowing users to adjust the bale size and weight according to their specific needs. This flexibility makes it easier for businesses to tailor their recycling efforts and adapt to changing market demands, ultimately maximizing the value of their recycled materials.

The Environmental Impact of Plastic Bottle Baler Innovations

Plastic bottle baler innovations not only improve the efficiency of recycling but also have a positive environmental impact.

Reduced Transportation Costs

By compressing plastic bottles into dense bales, the transportation of recycled materials becomes more cost-effective. Fewer trips are required to transport the same amount of material, leading to reduced fuel consumption and lower carbon emissions. Lower Landfill Usage.

One of the most significant environmental benefits of plastic bottle baler innovations is the reduction of landfill usage. Compressed bales occupy less space, leaving more room in landfills for non-recyclable waste. This contributes to a cleaner and more sustainable environment.

Applications Across Industries

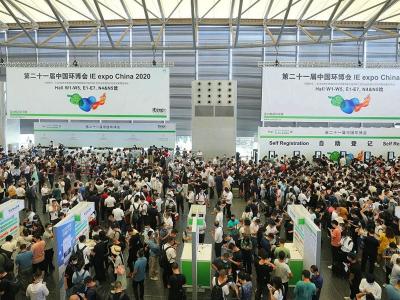

Plastic bottle baler innovations have found applications across various industries, including retail, manufacturing, and waste management.

-

Retail: Supermarkets and retailers use balers to efficiently manage plastic bottle waste generated on their premises.

-

Manufacturing: Manufacturing facilities implement balers to streamline their recycling processes and reduce waste disposal costs.

-

Waste Management: Recycling centers and waste management companies use these innovations to improve the processing of plastic bottles and maximize the recycling rates.