Artisanal craftsmanship has always been associated with high-quality products. Whether it's handmade clothing, accessories, or home décor, the level of expertise and attention to detail in these products is unmatched. One crucial aspect of the production process is the use of a wool bale press. In this blog, we will delve into the significance of the wool bale press, its role in manufacturing handmade wool products, and how you can find a wool bale press for sale to enhance the artisanal craftsmanship in your own creations.

The Essence of Artisanal Craftsmanship

Artisanal craftsmanship is all about preserving traditional techniques passed down through generations. It values the uniqueness and individuality of each product, handcrafted with love and care. One industry that greatly benefits from this approach is the production of wool products. The process of creating handmade wool items requires various specialized tools, including the wool bale press.

The Role of the Wool Bale Press

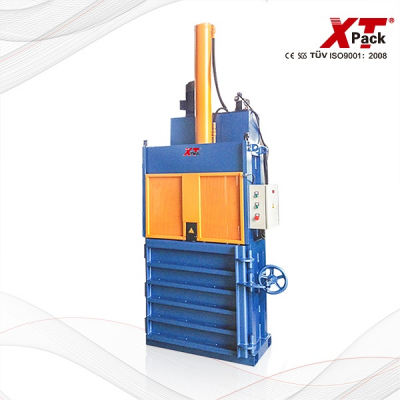

A wool bale press plays a crucial role in the manufacturing of wool products. It is specifically designed to compress large quantities of wool into compact bales, ensuring efficient storage and transportation. The press applies immense pressure to the wool, compacting it tightly while maintaining the integrity and quality of the fibers. This process not only saves space but also protects the wool from external elements, such as moisture and dust.

Benefits of Investing in a Wool Bale Press

Investing in a wool bale press offers several benefits for artisans and manufacturers of handmade wool products. Firstly, it allows for improved productivity and efficiency in the production process. With a wool bale press, more wool can be processed in a shorter amount of time, increasing the overall output of the operation.

Furthermore, a wool bale press ensures consistent and uniform bales, which is crucial for maintaining the quality of the wool. The press's ability to apply the right amount of pressure guarantees that the fibers remain intact and undamaged. This ensures that the final product retains its softness, warmth, and durability.

Investing in a wool bale press also demonstrates a commitment to sustainable practices. By compressing the wool into tightly packed bales, less storage space is required, minimizing the carbon footprint and transportation costs. Additionally, the press promotes waste reduction as it maximizes the usability of the wool, leaving minimal scraps or leftover materials.

Finding a Wool Bale Press for Sale

Now that you understand the importance of a wool bale press, you may be eager to find one for your own artisanal wool production. Luckily, there are various resources available to purchase a wool bale press for sale. Numerous manufacturers specialize in producing high-quality wool bale presses that cater to different production scales and budgets. You can explore online marketplaces, machinery suppliers, or even reach out to industry experts for recommendations.

Artisanal craftsmanship is an integral part of the handmade wool product industry. The use of a wool bale press is essential in maintaining the quality and efficiency of production. By investing in a wool bale press, artisans can enhance their productivity, ensure consistent quality, and contribute to sustainable practices. With a plethora of options available, finding a wool bale press for sale has never been easier. Elevate your artisanal craftsmanship and take your handmade wool products to the next level!