In healthcare facilities, waste management plays a crucial role in maintaining cleanliness, hygiene, and sustainable practices. With the increasing amount of waste generated daily, healthcare organizations are continuously seeking innovative solutions to minimize waste and promote environmentally friendly practices. One such solution that has gained significant popularity is the aluminum baler. In this blog post, we will explore the benefits of using an aluminum baler for healthcare waste reduction, ensuring a greener and healthier future for all.

The Importance of Waste Reduction in Healthcare Facilities

Healthcare facilities produce a substantial amount of waste, including plastic wrappers, packaging materials, disposable gloves, and a myriad of other single-use items. By implementing waste reduction strategies, healthcare organizations can mitigate environmental hazards, conserve resources, and reduce disposal costs. Incorporating an aluminum baler for compacting and recycling aluminum waste proves to be a valuable investment towards achieving sustainable waste management goals.

Why Choose an Aluminum Baler for Healthcare Waste?

Aluminum waste, such as empty cans, foil packaging, and discarded intravenous fluid containers, is commonly found in healthcare facilities. An aluminum baler efficiently collects and compacts such waste, reducing its volume by up to 95%. By compacting aluminum waste, healthcare facilities can maximize storage space, streamline waste management processes, and minimize the frequency of waste collection and disposal. This not only eliminates potential safety hazards but also significantly reduces operating costs associated with waste management.

Advantages of Using an Aluminum Baler for Sale

-

Efficient Waste Management: An aluminum baler ensures efficient waste management by compacting a significant amount of aluminum waste into compact bales, allowing for easier storage, transportation, and recycling. This leads to more sustainable waste management practices within healthcare facilities.

-

Financial Savings: By reducing the volume of waste, healthcare organizations can optimize waste collection schedules, resulting in reduced labor costs, transportation fees, and disposal expenses. Additionally, recycling the compacted aluminum bales fetches a competitive market price, generating potential revenue for the facility.

-

Compliance with Regulations: Many governments and regulatory bodies have imposed strict regulations and targets on waste reduction and recycling. Implementing an aluminum baler ensures healthcare facilities adhere to these regulations, avoiding fines and penalties while leaving a positive impact on the environment.

Factors to Consider when Purchasing an Aluminum Baler

When searching for an aluminum baler for sale, it is essential to consider the following factors:

-

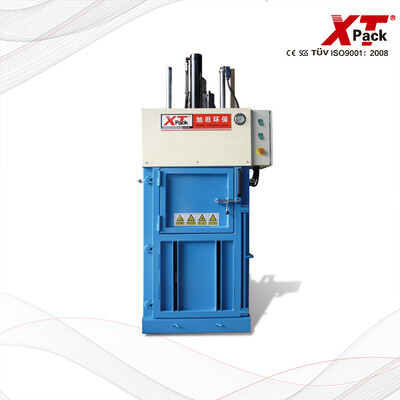

Durability and Reliability: Choose an aluminum baler from a reputable brand known for its durability, reliability, and efficient after-sales support to maximize the lifespan and productivity of the equipment.

Incorporating an aluminum baler in healthcare facilities is an investment that pays off in the long run. By reducing waste volume, promoting recycling, and streamlining waste management processes, healthcare organizations can significantly contribute to environmental conservation while enjoying financial savings. Investing in an aluminum baler for sale is a wise decision that not only aligns with sustainability goals but also ensures a healthier and greener future for generations to come.