In the process of production, life, as well as industrial and agricultural production, a large amount of waste paper and waste materials are generated. These waste products are collected for centralized processing and reuse. In order to save space and transportation costs, the waste paper needs to be compressed and packaged before recycling and transportation. The current waste paper baling machine requires manual filling, opening, baling, and removal of the package, with low efficiency. Moreover, the package of the current baler is pushed out from the rear to the exit for steel wire tying, and the pushing process can easily cause the package to scatter, resulting in rework and time and effort consumption.

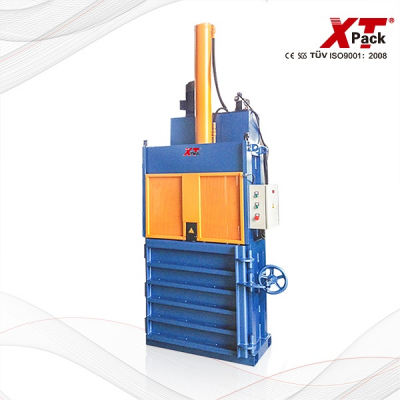

The full-automatic waste paper baling machine consists of the baler body and the feeding device

The machine baler body includes the material channel, inlet, main hydraulic system, and tying device. The material channel is a horizontal rectangular frame structure, and the upper end of one side of the material channel is equipped with an inlet. The main hydraulic system is installed on one end of the material channel horizontally. The full-automatic waste paper baling machine's main hydraulic system includes a hydraulic cylinder for transverse compression of materials in the material channel.

The other end of the frame is the exit of the baler, and the tying device is coaxially installed with the baler exit. The feeding device is set outside of the material channel on the side of the inlet. The feeding device is equipped with a synchronous belt driven by a stepper motor. The belt is uniformly arranged with multiple feeding plates that transport materials from bottom to top.

Performance characteristics of the full-automatic waste paper baling machine

-

The Full-automatic waste paper baling machine can automatically detect and continuously package materials, which can also be manually operated. It can be used for packaging waste paper, cardboard boxes, newsprint, waste plastic, PET bottles, plastic film, turnover boxes, straw, etc. with good packaging effect.

-

It has fast packaging speed, saving time and electricity, low failure rate, high automation, labor-saving, high reliability, and long service life.

-

It adopts double reinforced packaging to prevent scattered packages during pushing and final tying, with good packaging quality, reliability, and efficiency improvement.

-

The feeding device is equipped with multiple evenly distributed baffles to prevent material slipping, and the material is uniformly transported from bottom to top into the material channel of the machine baler.

-

The Full-automatic waste paper baling machine has a reasonable structure, simple operation, reliable use, and is easy to promote and apply, effectively improving production efficiency.

Good packaging equipment must have sturdy parts with long life spans. For a waste paper baling machine, its life span depends on several critical parts. When these critical parts reach the point of obsolescence or require major repairs, the entire waste paper baling machine cannot continue to operate. Therefore, when considering the life span of parts, the life span of the main parts should be taken as the basis, and the life span of other parts should not be smaller than that of the main parts, and should not exceed the life span of the main parts, nor should the vulnerable external parts of the waste paper baling machine be included in this range.